Did you like the article? Share it!

How can I overprint my self adhesive label without ruining it?

Overprinting an exhisting label means adding an additional layer of text or graphics on your label after it has been printed.

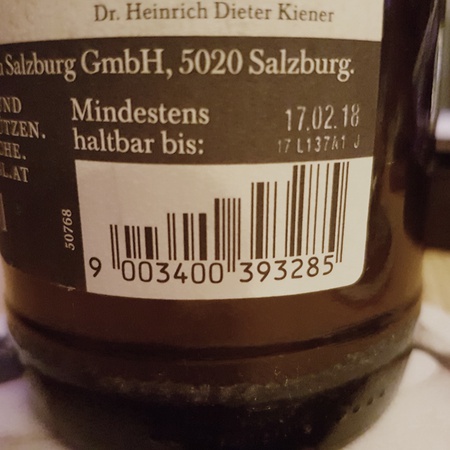

Even if our core business is built around printing custom labels ready to apply on your products, many manufacturers and distributers are able to take their custom self adhesive labels and add some additional data such as BBE dates, batch number, alcohol percentage etc.

Generally this kind of label has their brand logo printed in full-colour, premium-quality print and a section is left vacant to allow space for some variable informations.

There are a multitude of uses for overprint labels in nearly every industry. Some of these include:

- Product descriptions

- Weight

- Package size

- Ingredients

- Batch Information for traceability

- Barcoding

- Sequential numbering

To finalise these labels, you need to overprint them through several methods such as thermal transfer, direct thermal or inkjet printing. However before you start overprinting your labels you do need to consider the appropriate material for your application and the right printing method based on which information you need to print.

Let's see more in depth these types of printing methods and their features.

How does Thermal Transfer Printing Work?

The process of thermal transfer printing is whereby heat transfers the colour pigment of a thermal transfer ribbon onto the label substrate; generally this type of printing machines use roll labels. This printing method is ideal for printing barcodes, bottling data or best before dates. For thermal transfer printing you need a special thermal transfer printing machine with a high-quality thermal transfer ribbon. Due to the printing technology, only one colour can be printed at a time in thermal transfer printing. The colour dipends on the ribbon used.

Thermal transfer printing is the highest quality printing method to overprint your beautiful roll labels without ruining them. Moreover it lasts longer than direct thermal printing (read on to find our more about direct thermal printing.

Before you choose to print labels via thermal transfer, we recommend you perform testing. There are many factors that influence the print result. For example, the font should not be too small or thick, the label material must be suitable for the process and the temperature must be right in order to achieve a high-quality print image. If the temperature is too low, the transfer will not be successful. This type of overprinting method can be used in many industries and application fields for example food products labels, equipment or other products. In order to apply the appropriate EAN code, the best-before date or the filling data to your labels, we recommend producing high-quality roll labels as pre-printed “master labels” from a professional label printer and to overprint sensitive data with the thermal transfer printer. The choice of paper or film depends strongly on the final use of the labels and your quality requirements. We can suggest you the best substrate based on your needs.

What is Direct Thermal Printing and which is the difference to Thermal Transfer Printing?

Direct thermal printing uses chemically treated, heat-sensitive media that blackens when it passes under the thermal printhead, while thermal transfer printing uses a heated ribbon to produce durable, long-lasting images on a wide variety of materials.

A specific printer/technology must also be used; a print-head inside the printer moves over the paper and heats it to create an image. A chemical reaction takes place at the heated areas and the aforementioned, special paper turns black. In contrast to thermal transfer printing, direct thermal printing can only be used for monochrome black printing.

Because they print without a ribbon, direct thermal printers are noted for their simplicity. In addition, the print result is very sensitive to UV radiation and fades quickly. If the label is overexposed to heat, light, or other catalysts, the material will darken and make the text or barcode unreadable. For these reasons, direct thermal printing is not used for lifetime identification applications. So if you're looking to the right method to overprint your wine or food label this is not the method for you. The direct thermal printing is used to create for example barcodes ore simple text. If you have a direct thermal printer consider our Thermal Paper as substrate for your labels.

How does Inkjet Printing work?

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto a substrate. Inkjet printers are the most commonly used type of printer, and range from small inexpensive consumer models to expensive professional machines. Usually this kind of printers is configured inline on the labelling machines. One of the main problem of the inkjet printing method is the conflicting requirements for a coloring agent that will stay on the surface vs. the rapid dispersement of the carrier fluid. The most frequently used inks are aqueous inks based on a mixture of water, glycol and dyes or pigments. These inks are inexpensive to manufacture, but are difficult to control on the substrate and they require special coating or lamination before printing to make them long lasting.

For this reason a majority in professional use today employ a much wider range of inks, for example solvent inks or UV-curable inks.

Can I use Labels from oppaca.com in my Printer?

The answer is YES. Bu first of all you need to know which kind of printer you use and which result you want to obtain on your self-ashesive labels. Most of our standard materials and finishes can be used within the thermal transfer printing process. However, this only applies to thermal transfer printing, not to direct thermal printing, for which there is only one specific material (the thermal paper mentioned before). To ensure you that the overprintable labels suit your needs we need also some other informations such us the required roll core diameter (76 mm, 45 mm), the maximum roll diameter as well as the number of labels per roll and the winding direction during the ordering process. These informations are specificied on the technical sheets of your printer.

We're here to help you answering your questions about how to overprint your wonderful labels, which kind of substrates are suitable to your needs and of course print your overprintable labels.

Contact us throught this form and a member of the Oppaca Staff will reply as soon as possible.

Next