Did you like the article? Share it!

Screen printing: everything you need to know

Screen printing is one of the oldest printing methods, but still widely used today in various sectors due to its versatility. From the Phoenicians to Andy Warhol, it has been a favourite technique for transferring a design onto a medium, so even if you've never heard of it before, chances are you've worn or used a 'screen printed' product without even realising it.

To trace the origins of screen printing, we need to go back to the Far East; the inventors were probably the Phoenicians. It then spread to China and Japan to land in Europe only in the eighteenth century, thanks to the expansion of the silk trade. Finally, towards the end of the 19th century, screen printing became the undisputed queen of mass printing in advertising and has since been widely used in many sectors.

In terms of packaging, screen printing is a great way to make your product stand out because it allows you to highlight some aspects of your design, thus creating a nice three-dimensional effect. Thanks to screen printing, you can give that extra sprint to your packaging and, with it, to your product, expressing all your creativity.

For a company or a brand, presenting its product in the best possible way is a fundamental aspect of marketing. A product must be able to conquer the consumer, and unique and captivating packaging allows him to do so.

So, having understood this process's historicity, beauty and usefulness, let's see in more detail what it is and how it can be used to embellish packaging. In this article, you will find everything you need to know about screen printing; Here are the points we will address:

How does screen printing work?

The step-by-step screen printing process

What is screen printing?

Screen printing is one of the oldest printing processes. It is used to transfer ink onto another support of any type (paper, plastic, wood, fabric, etc.) through a printing matrix. The most commonly used substrates in screen printing are paper and fabric, but also other materials such as metal, wood and plastic. It is a prevalent technique for several reasons, primarily because of its versatility.

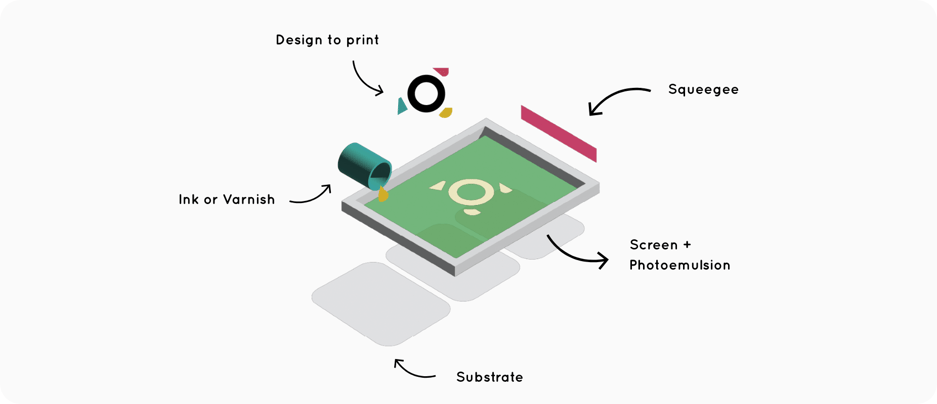

It involves using a sort of "stencil" in technical jargon called a screen printing frame, which is treated photographically to be prepared with the image to be reproduced. Then, using a rubber tool, which moves back and forth, the ink is pushed through this stencil, and onto the underlying substrate, creating the image.

Screen printing can deposit very thick layers of ink on almost all surfaces, creating a relief effect that is very pleasant to the touch. It also offers various benefits, graphic and otherwise, compared to other printing methods. We will see this later; now we understand better how it works.

How does screen printing work?

Screen printing can be done by hand or machine, but the basic process is always the same, and both methods require the use of a "printing matrix", in this case, called a screen printing frame. The screen printing frame is made with a synthetic polymer fabric mesh mounted and then stretched over a support frame, which can be made of metal or wood. The tension of the knit can be measured with a tensiometer; the unit of reference is Newton per centimetre (N/cm).

Creating a screen printing frame requires a meticulous and accurate pre-press phase. The drawing must first be prepared digitally; then, through a photo engraving process, it is recreated on edge. After which, a water-based emulsion is spread on the shirt's surface; this water-soluble film's coated fabric is then exposed to ultraviolet light through a photographic film. The photographic film has black areas corresponding to the graphics to be reproduced and areas transparent to light in the other parts, which must not be reported.

Through the photoengraving process, the emulsion where it receives light hardens, while it remains water soluble where the film is black and not receiving light. In practice, after a simple washing with water, the screen printing frame develops, revealing the free areas of fabric and letting the paint/ink pass, allowing the original design to be transferred.

A bar with a rubber edge, called a "squeegee", is used to press the paint/ink evenly onto the frame. This is resting on the texture of the fabric and moving back and forth, causing the ink to pass through the free part of the mesh, homogeneously recreating the desired graphic. The fabric meshes can have a more or less dense weave to be more or less porous and to obtain differently defined details.

The step-by-step screen printing process

Step 1. Design creation and prepress phase

The design to be reproduced is created or checked by a prepress employee. The operator carefully checks every aspect to ensure that the design can be optimally realised in print. This initial phase may seem trivial, but it is essential and determines the success or otherwise of the work.

Step 2. Creation of photographic film

The printer takes the design they want to create on the finished product and prints it onto clear acetate film. This will be used in the next step to make the frame.

Step 3. Preparing the frame

A frame with a fabric texture suitable for the complexity of the design to be printed is chosen, after which it is coated with a layer of light-reactive emulsion, which hardens thanks to the photo engraving process, giving life to the matrix of the design.

Step 4. Photo engraving of the frame

The acetate film with the design is placed on the emulsion-coated frame, and the whole is exposed to intense light for a preset time. The light hardens the emulsion, so the parts of the screen covered by design remain liquid. Next, the unhardened emulsion is rinsed to allow the ink to pass through. Finally, the frame is ready to be used.

Step 5. Screen printing

The frame is positioned on the printing machine in the same way as the label, packaging, or garment to be printed. The ink or varnish is added to the surface of the frame and a palette knife moving back and forth pulls it along the entire length, distributing it evenly. In doing so, the ink or paint is pushed through the open areas of the frame, imprinting the design on the underlying support.

How to use screen printing?

The possibility of creating thickened and three-dimensional effects still makes screen printing a highly appreciated fashion and luxury packaging technique. Moreover, it remains the best solution for all those "special effects" that involve glossy, opaque, metallic, luminescent, scratchable or embossed inks, which greatly embellish a print!

It can be used on almost any type of material, and it is precisely because of this versatility that, in recent years screen printing on books, brochures, paper napkins, diaries, notepads, calendars, boxes, adhesive labels, etc., experienced an unprecedented increase. In short, there are many uses for screen printing.

Once we understand the characteristics of this process, however, before jumping into the choice, we must ask, "What do we want to communicate with our packaging?". Naturally, screen printing is highly recommended in all those cases in which a modern and minimal effect is to be obtained, but also in those "premium" occasions in which elegance and luxury are communicated through the "less is more" and the addition of refined details.

Screen printing: the benefits

When opting for screen printing, it is worth considering this method's advantages. Let's see some of them:

1. Versatility. One of the main advantages of screen printing is its versatility. As mentioned in the article, it can be used on any material, fabric, plastic, wood, glass or even metal, and it is also possible to use multiple colours. In short, there is almost infinite design freedom.

2. Durability. Compared to other methods, screen printing allows you to apply a wide coverage of ink… the result? What is produced with this type of printing proves to be a durable design over time. Furthermore, due to the very nature of the pigments and binders, they also prove to be very resistant to light, mechanical abrasion, scratches, and humidity, allowing screen-printed products to be used even outdoors without getting damaged.

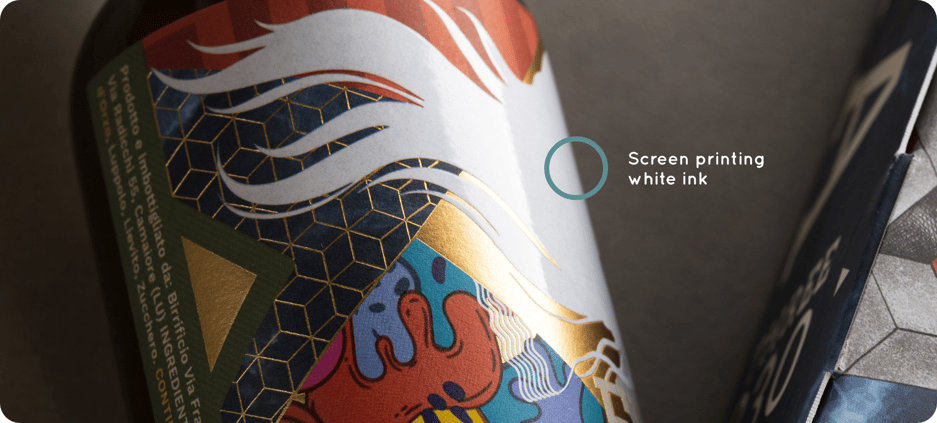

3. Coverage. Screen printing allows even thick layers of paints and inks to be applied, guaranteeing high opacity, even in particular colours such as white.

4. Convenience. Screen printing is a cost-effective method in the long run. Once setup is complete, it is relatively quick and easy to print items in high volume. So, it's safe to say that the more you print, the cheaper the unit cost.

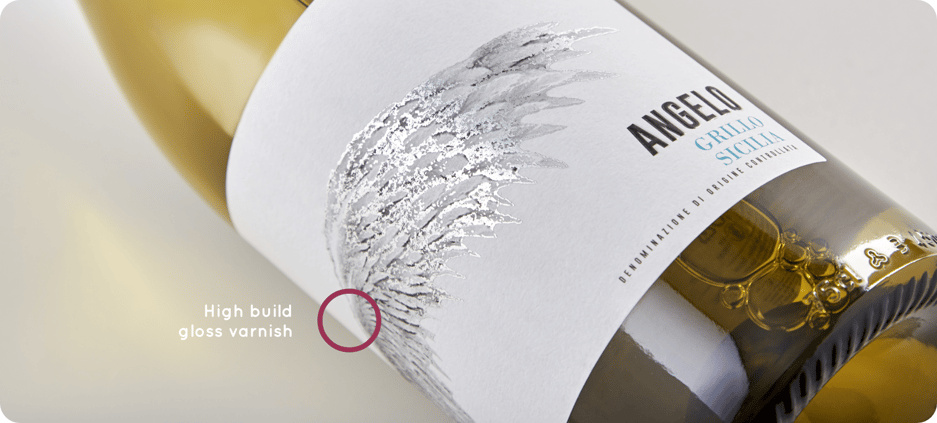

5. Highlight effect. The thickness and gloss of the silk-screen varnish create a "lens" effect which highlights the underlying colours; silk-screen printing is ideal for creating glossy details or 3D effects that emphasise certain elements, such as the product name or logo.

Despite the advantages, screen printing also has some minor limitations. For example, it would be better to avoid it in those cases where the details to be highlighted are too small or delicate or the surface to be screen printed is too large. This is because fine details are difficult to reproduce on the frame and, consequently, on the support, while too large areas make labelling or packaging composition difficult.

Other notes to make… Screen printing cannot reproduce nuances and is not recommended for elements that could vary with each order, such as the vintages of wine; this is not that it cannot be done, but it would mean creating new systems or looms each time, thus having to bear higher costs.

Screen printing on Oppaca

Deep and opaque colours with screen printing. Screen printing is used to reproduce coloured images on the chosen substrate through a thick layer of ink. One colour is printed at a time, so multiple screens are required to produce a multi-colour image or design, to be precise, one for each shade. Furthermore, depending on the type of screen printing frame (more or less tight mesh), deep and more opaque colours can be obtained.

Screen printing with glossy transparent varnish. This type allows you to highlight some graphic elements of your design, creating a glossy three-dimensional effect thanks to a specific varnish. On Oppaca, you can choose this type of finish; it is recommended to embellish your label visually and to the touch and thus highlight elements such as the name or logo of your brand.

The ideal substrate for screen printing. Beautiful crafting isn't enough here at the Oppaca site without the perfect substrate. The ideal combination is the key to a successful label. For this reason, we want to suggest some excellent substrates for screen printing your label; here are some:

• Natural papers: papers with an untreated appearance, characterised by particular textures, natural colours with different shades of white or ivory and different weights of paper.

• Matt Anti-pulping Coated Paper: it is a matt wood-free paper, coated off the machine; resistant to wet because it is equipped with an anti-pulping treatment.

• Opaque polypropylene: is a white, opaque polypropylene film with a top-coated treatment.

Excellent, I would say that at this point, we have thoroughly explored the screen printing topic; now, you have to try to use it and test it directly yourself. Use our online estimate by selecting the Silk-screen varnish option in the "Processing" section and create your perfect packaging! Do you need answers, or do you want to learn more? Please write to us; the Oppaca team is at your disposal!

Next