Did you like the article? Share it!

What is CMYK? What is it used for (in the printing industry)?

Let’s finally find out the real meaning of it.

CMYK is a scheme for combining primary pigments.

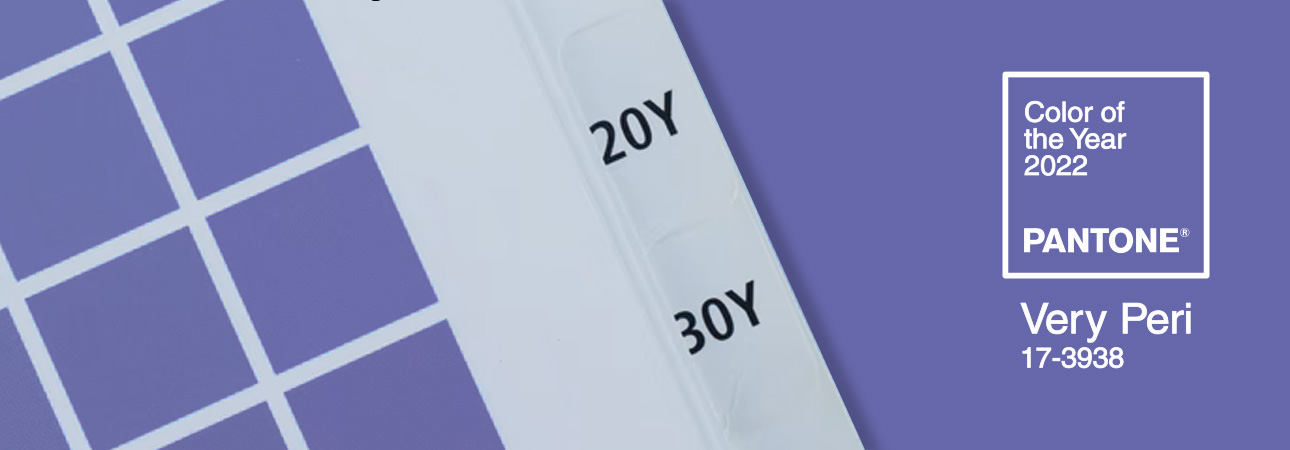

The C stands for Cyan, M stands for Magenta, Y for Yellow, and K for Key. The key color in today's printing world is black but it has not always been. During the early days of printing, the colors used for Key have been brown, blue, or black whichever was the cheapest ink to acquire at any given time. Technically, adding equal amounts of pure cyan, magenta, and yellow should produce black. However, because of impurities in the inks, true black is difficult to create by blending the colors together. This is why black (K) ink is typically included with the three other colors. The letter "K" is used also to avoid confusion with blue in RGB

(For more infos about RGB, go check our article "What is RGB? What it is used for?” on Oppaca blog).

Basically CMYK are the four basic colors used for printing color images.

Which are the main features of CMYK color model?

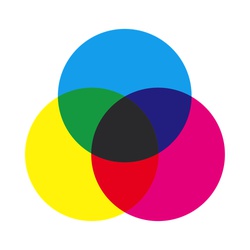

CMYK colors are "subtractive". This means the colors get darker as you blend them together.

The CMYK pigment model works like an "upside-down"version of the RGB (red, green, and blue) color model.

The primary colors RGB, combined at 100-percent brilliance, produce white. The primary pigments CMY instead, combined at maximum concentration, produce black.

CMYK color has a wider range of colors though is limited compared to the RGB color profile.

So why don’t we use RGB color values to print colored images? We’ll show you some good reasons.

While there are a select number of rare printers that use RGB, there are a multitude of practical reasons CMYK printing will be the dominant model for a long time. To understand why printers generally don’t use RGB, we have to understand a few things. On a monitor or projector, combining RGB colored light creates lighter colors great if you have a dark screen.

However, on print materials, colors are produced differently from how they are made on a computer monitor. Layering RGB inks on top of or close to each other produces darker colors because inks can only absorb and reflect different colors in the light spectrum, not emit them. RGB colors are already dark to begin with. This makes it difficult to produce lighter colors such as yellow or lime green as adding RGB colors will invariably result in much darker hues.

Why we need to use CMYK model for our labels?

Using a CMY color model provides a workaround for this problem as cyan, magenta, and yellow are lighter than red, green, and blue. CMY will be able to cover most lighter color ranges quite easily, compared to using RGB. However, while CMY by itself will not be able to create very deep dark colors or a “true black,” so black (designated “K” for “key color”) is added to CMY so a much wider range of colors can be achieved compared to just RGB.

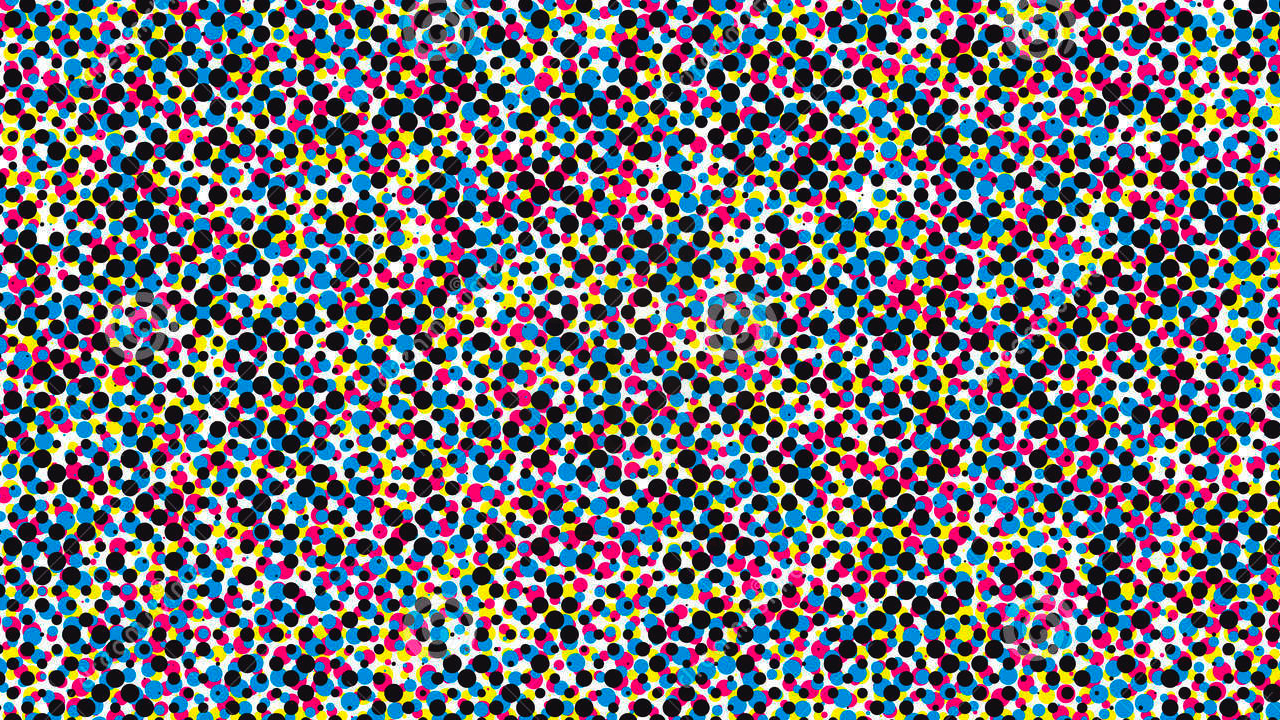

If we look at a micro-level, CMYK inks are applied in set patterns of tiny dots that appear to create a solid color in a way similar to the pixels on a digital image.

Layers of these dots in different amounts of ink create any shade or color.

This process is called half-toning.

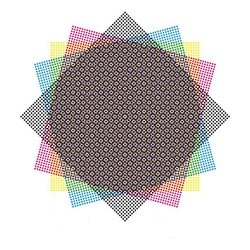

These patterns are placed into the shape of a screen, 1 for each component (CMYK). Each screen has a different angle.

These different angles are used to avoid some printing difficulties such as Moiré and increase print quality.

After explaining to you all the main features of CMYK model in the printing process, let’s give you some advices to create the perfect printing file.

So what is our advice for you to create the perfect file before printing?

In general, the RGB mode should be used when preparing graphics intended mainly for viewing on computer displays.

The CMYK mode should be used when creating illustrations for print media.

Having understood this feature, we really recommend starting your project in CMYK or at least converting from RGB before you send it in for printing for a few reasons. The apparent color change from RGB to CMYK can be dramatic in many cases, such as when your artwork has a lot of bright red in it. If you desire the best possible color accuracy on your final prints, you will want to consistently set the color models for your design files before submission.

Obviously, the Oppaca staff will keep an eye on the right reproduction of colors on your label.

If you need answers about CMYK and its application in the printing industry or you want to learn more about a particular topic, write us with this form, and a member of the Oppaca staff will respond as soon as possible.

Next