Did you like the article? Share it!

Why don't printed colors match what I see on the screen?

Since the early days of desktop publishing, photo editing, and graphic design, professionals and hobbyists alike have had to deal with color shifts, seeing one color on a monitor but getting different results when the document, photograph, or artwork is printed. For example a red apple on a monitor comes out orange or plastic-looking bright red when printed.

Why is this happening? Let's see it more in depth.

1. Opposite Base Colors

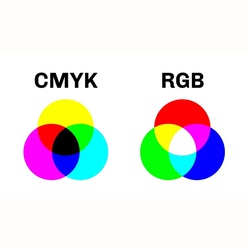

Well, the simplest answer is that monitors and printers see colors differently. In other words, they use different color models to produce the same hues. Monitors combine red, green, and blue (RGB) to display the colors you see, while most printers combine cyan, magenta, yellow, and black (CMYK) to reproduce colors. To know more about CMYK and RGB colors please check our articles "What is CMYK? And what it is used for (in the printing industry)?" and "What is RGB? An what it is used for?" on our blog.

2. Different Desktop calibrations

When you walk into a major electronics store, they have dozens of flat screen TVs displayed on the wall, all playing the same video. If you stand there and pay attention at the images on the different screens, you're going to notice the picture looks slightly different on each one. Brighter whites or deeper blacks, warmer or cooler tones, less or more contrast, etc. Every TV varies because of screen type, contrast ratio, color calibration, the room's lighting and even the data transmission hardware.

The same thing happens with your monitor. Screen type, computer type, application version, calibration settings, color profiles, driver types, and so on all have an impact on the display color and the printer output color. Every monitor has a different setting. This is the reason why the colors we see on our monitor are different from the one you see on yours.

In order to solve this issue, professional printers generally calibrate their monitor by using a software or a special calibration equipment for example the i1Display Pro from X-Rite.

When you calibrate, you’re optimizing your monitor for contrast, brightness, and color temperature. This means you’re not working on a monitor that is displaying the wrong color, so it’s easier to make good design and editing decisions.

3. Paper influence

Yes…paper. The substrate itself on which your label is printed really does make a difference! An “all paper is the same” approach is not right at all. A coated paper has a shiny gloss coating on the surface, and the ink sits atop the coating allowing for minimal ink absorption. On the contrary an uncoated paper has no surface coating permitting maximum ink absorption into the paper. This means that for sure a coated paper such asWater-resistant Glossy Coated Paper or Glossy White Polypropylene will make the printed colors brighter more similar to what you see on the screen.

To know exactly which will be the result on an uncoated paper such as Water-resistant Felt-marked Paper usually a professional printer use a specific Profile on its monitor based also on the printing system.

4. Right printing partner

Most graphics software have a setting for color management. If you let the software do the work, you will still get good results by turning color management off. Color management is primarily intended for a pre-press environment. Not everyone needs it. If you're not doing professional printing, first work without color management before you assume you need it.

The best solution is always to rely on the exprerience of the printing partner you're choosing.

Labelado will always help you to obtain the best result from your file.

5. Printing Proof

Do you want to be sure about how your label will look like when it will be produced? Would you like to see if the printed label will look like that one that you saw on your laptop?

No problem! Thanks to a printing proof you can see your finished label and judge the colors. Order your printing proof here.

Next