Did you like the article? Share it!

What is a stamping plate?

You may have heard this word: Stamping Plate. But what does it mean? Today we talk about the stamping plate for hot foil and embossing, their function and their use in the world of printing!

When we talk about " stamping plates", we mean all those printing plates that are used to carry out various finishings, mainly hot foil, embossing and debossing. These stamping plates are also physical elements that are installed on printing machines to be able to print noble elements or emboss the substrate directly.

These printing systems can be used both for flatbed printing and reel printing and can therefore take the form of both plates and cylinders, which can be fixed to the appropriate sections of the printing machines with screws and hooks.

Hot Foil Stamping plate

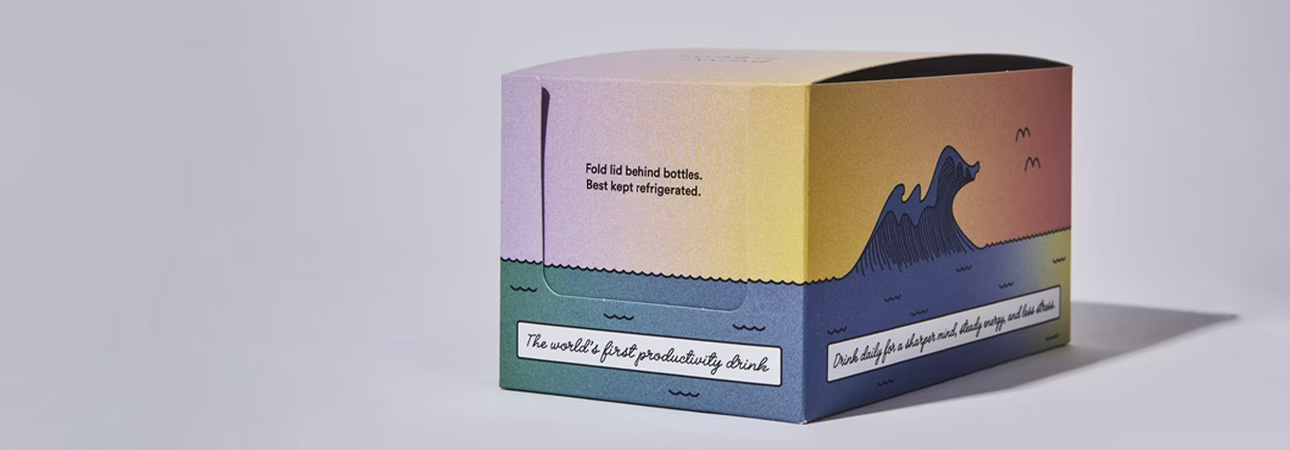

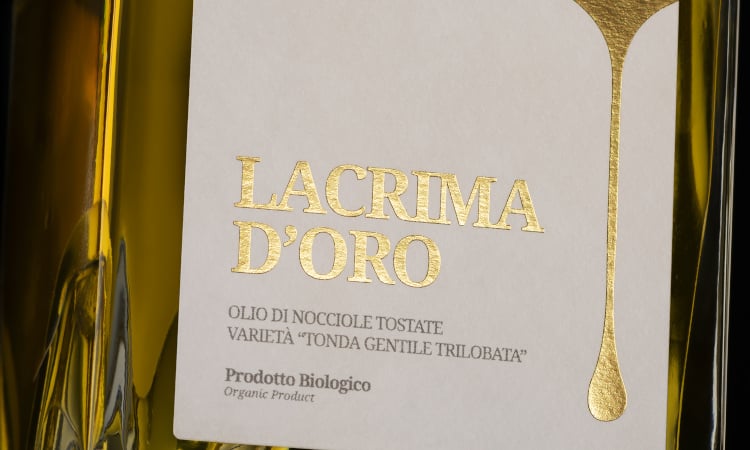

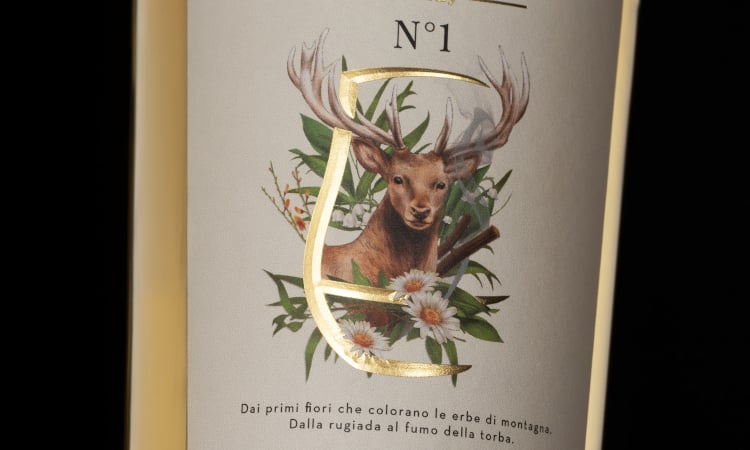

By hot foil stamping plate we mean the stamping plate that is used to print the hot foil on paper or plastic substrate for labels or packaging.

Therefore, once the plate is fixed to the appropriate printing section, it is heated to temperatures between 120 ° and 180 ° (this depends on the heating technology of the printing section, which can heat up with oil or resistances). The temperature, combined with the pressure of the plate on the substrate will allow the transfer of the metal foil.

This operation requires both time and a few sheets / meters of setting up to be able to obtain the optimal result. At that point, production can begin at the speed that allows the best printing result.

Basically, according to the foil and the type of paper / plastic on which it will be necessary to print, there will be certain pressures and temperatures to be respected.

Foil may be difficult to print on certain substrates and may not stick properly on painted items. Some foils allow to be overprinted, allowing you to add details with other printing methods (offset, flexo, screen and digital).

Embossing stamping plate

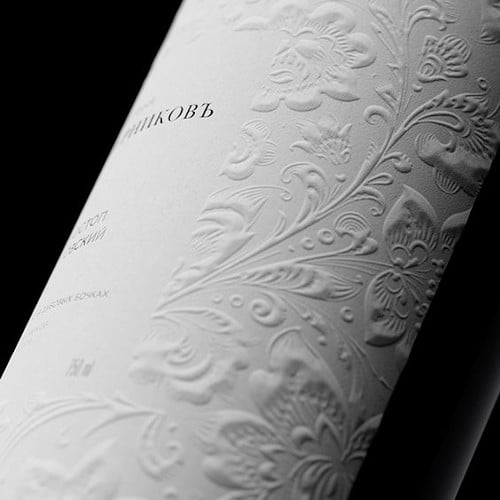

Dry embossing needs a two-component printing plate, unlike the hot foil stamping plate which is one-component. The printing plate for making the dry embossing is composed of two elements, called "male" and "female". These two elements must fit together perfectly.

The female is the component hollowed out in metal (magnesium or brass) while the male is a plastic element that forms the relief that must match the female. This last element is generally thermoformed directly on the female to ensure perfect adhesion.

Una volta impostati sulla macchina (sia essa a foglio o a bobina) il maschio e la femmina devono chiudere a sandwich la carta scelta, e la loro pressione andrà a formare un rilievo, deformando la carta con il soggetto inciso.

Once set on the machine (be it sheet or reel) the male and female must sandwich the chosen paper, and their pressure will form an embossing, deforming the paper with the engraved subject. Generally this process is done cold without heating the plates, sometimes the substrate is helped to become softer in the process by heating it to 30 ° C - 40 ° C. Dry embossing also requires a setting up time to create register with the other elements of the label or packaging, for this it requires additional costs and extra setting up meters / sheets.

Since plastic tends to be elastic, it is not recommended to do dry embossing on it, it is advisable to make thick serigraphy in this case.

For adhesive labels, the dry embossing on important areas of the label could create problems for those who will label the product; this is because embossing could not guarantee perfect adhesion of the label to the product. It is always advisable to do an initial chat with a printing professional to know is embossign is the right choice. Sometimes an opaque screen printing could be done.

Debossing stamping plate

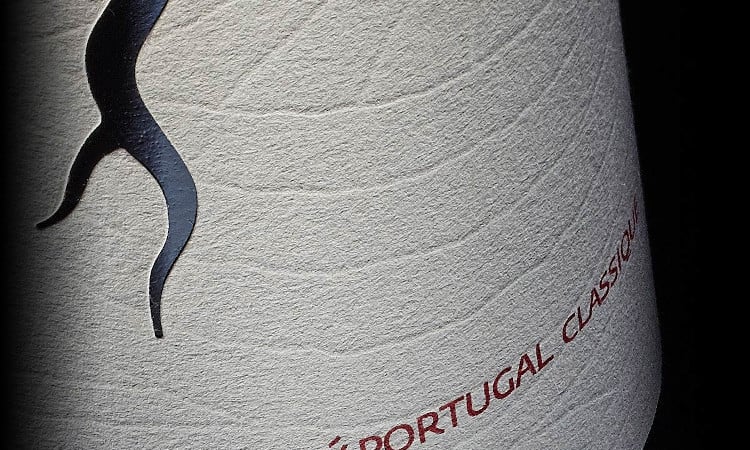

The debossing stamping plate is nothing more than a hot foil stamping plate, but is used cold and foilless to engrave paper. This process is the exact opposite of dry embossing; as the emboss lifts the paper, the debossing squeezes it down.

To make a nice debossing it is recommended to use thick and porous paper, especially for labels that tend to be thinner. To make it further visible it is also recommended to do it directly on the paper and not on dark colors, but at most very light shades.

Foil and Embossing printing plate

A very interesting finishing is the so-called foil and embossing printing plate at the same time, which as the name implies is nothing more than a hot foil but which, thanks also to the presence of a counter matrix, allows some elements of the foil to be embossed. This operation is very useful especially as it reduces 1 machine passage and in addition there is always a perfect register. These punches cannot be made of magnesium but only of brass, as they must be milled rather than produced with acid baths (we will explain these differences shortly).

Materials

Below are the most common materials that are used today for the production of stamping plates for hot foil, dry embossing and debossing.

- Magnesium: Magnesium is one of the most common metals for the production of stamping plates, it is inexpensive and extremely recyclable. Of all the metals in the list, it is the one that receives the most changes from the heat of hot working, in fact during its design it is necessary to count its widely at certain temperatures during the printing phase. Magnesium can be etched with acid baths.

- Copper: less used than magnesium, copper is a compromise between magnesium and brass, it costs slightly more than magnesium but is as durable as brass. Furthermore, like the latter, it does not receive thermal expansion like magnesium. Like magnesium, copper is etched with acid baths.

- Brass: brass is the king of punches, an alloy specially designed to perform at its best on any support. Brass costs much more than magnesium (3 or 4 times!) But allows for a durable and very high quality punch. The brass can, in the case in which it is necessary to make dry reliefs or with foil at the same time, be engraved three-dimensionally with a cutter. The latter operation cannot be obtained with magnesium and copper, which can only be engraved with an acid bath.

I hope this stamping plate guide has clarified your ideas about the world of hot stamping, embossing and debossing! If you want to know more write us using our form!Tips and tricks

Next